Open a packet of crisps or a bag of candy, and there it is: the shiny metallised film that keeps our snacks pleasantly crisp and fresh. Structurally, it is a polymer (often PET, polyethylene terephthalate) film coated with a thin layer of a metal, usually aluminium. The glossy looks of such metallised films are a comforting reassurance that our crisps and popcorn are protected from the oxygen and moisture in the environment, thus extending their shelf life.

But these metallised films have a less shiny side to them – their inability to be easily recycled and the high carbon footprint used in their production. Metallised films are also non-transparent, which is a distinct disadvantage when you want to show off the product inside your food packaging, and attract unsuspecting and hungry shoppers on their way to check-out.

So we decided to turn our attention to these current environmental and practical concerns over non-degradable plastics.

Our low energy alternative barrier coating for food packaging eliminates the metallic layer from the polymer packaging film – so not only is it much easier to recycle, completely non-toxic and mechanically stronger than metallised film, it is transparent and has a lower carbon footprint. It is even microwavable.

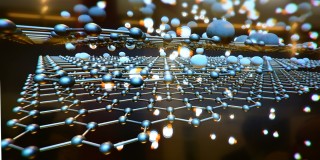

Our barrier properties arise from a synthetic inorganic material, a layered double hydroxide (LDH), which is prepared by a reconstruction method that allows the formation of high aspect ratio nanosheets. When embedded in a PVA (polyvinyl alcohol) matrix and coated onto a PET film, these nanosheets form what is essentially a complex labyrinth that oxygen or water molecules need to traverse in order to reach the food contained within the packaging (a mechanism known as the “tortuous pathway”). And much like the average person when they encounter a labyrinth: most of the molecules do not enter or eventually just go back the way they came, never reaching the crisps or popcorn we are protecting in the middle of the LDH labyrinth.

Because the LDHs we are using are entirely synthetic (unlike some clays that have been previously used in barrier applications), we can tailor them to be entirely non-toxic, free of any heavy metal traces. Consequently, non-toxic LDHs have been FDA approved as a safe food contact material.

Our experiments have shown the LDH-based barrier coatings to result in extremely low OTR (oxygen transmission rate) and WVTR (water vapour transmission rate) values, and their suitability has been further confirmed by theoretical calculations. We have quantified this improvement of barrier properties by introducing a barrier improvement factor (BIF), and determined that compared to a benchmark commercial metallised film, our non-toxic LDH nanosheet-based coatings give a BIF that is 40 times higher.

Introduction to a new 2D material: layered double hydroxid...

The interesting move of brand owners to Paper Packaging

By employing this new class of inorganic adjuvants, more e...