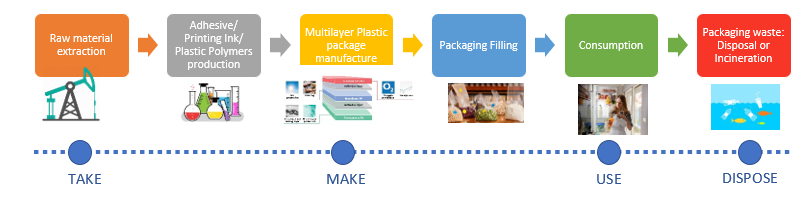

Today our consumption is following mainly the one-way processes of “Make-Use-Dispose” without recycling obligations.

For instance, when we buy food in a sealed pouch. After eating the content, we throw away the package and the pouch is most of the time finishing in a landfill or incinerated. So the resources to produce this package are lost.

This is called the “Linear Economy”.

Life Cycle of existing flexible film packaging

The linear economy model produces many negative impacts (e.g. resources consumption, environmental impact, …) at a global scale in which prompts the world to change.

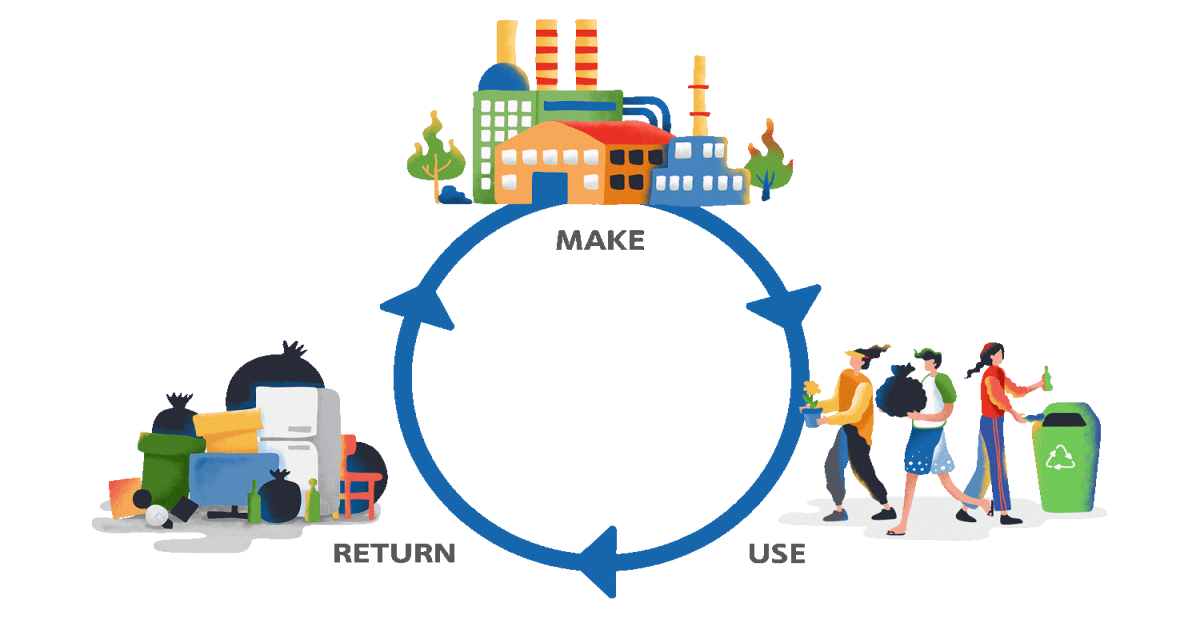

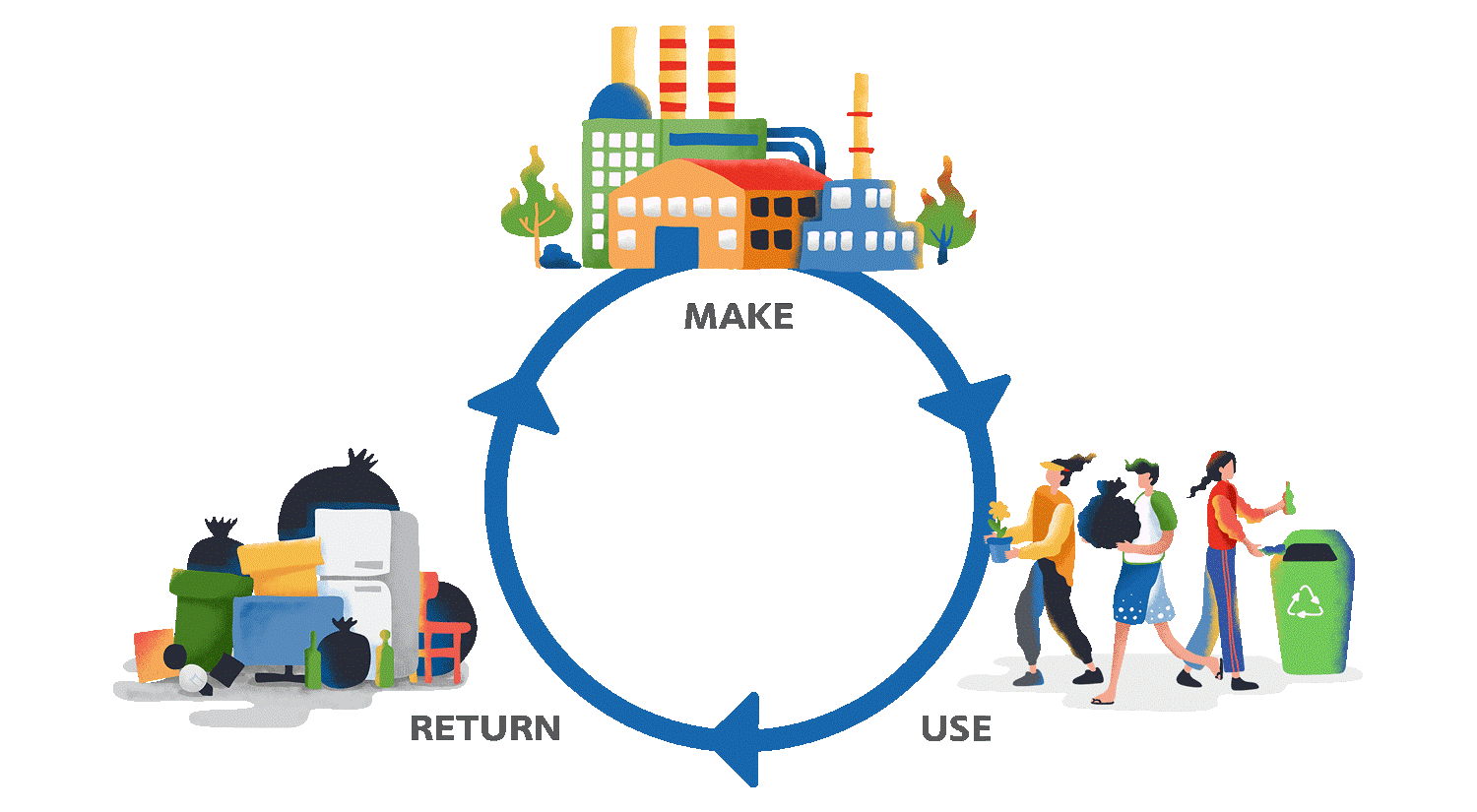

At the opposite, the Circular Economy is a regenerative economic system applied across the value chain to increase management efficiency of waste, raw materials, end-of-life products, and energy to circulate continuously in a proper closed loop system.

The Circular Economy is a new economic business model, offering a new way of looking at relationships between markets, customers and natural resources as well as harnessing the potential of emerging disruptive technologies to move from “Make-Use-Dispose” toward “Make-Use-Return.”

The goals and guidelines of the Circular Economy are to maximize the value of resources while minimizing the use of new resources by creating a series of circular approaches ranging from re-process, re-design, added value, innovation, collaboration with business and non-business related and reuse. The model is building better values and a more sustainable environment, community, society, and business.

How CIERRA™ contributes to Circular economy

CIERRA™ is a functional materials platform. In this platform, we are developing additives offering various properties such as flame retardant, chemical adsorbent, … and barrier for food packaging.

Usually, barrier property against oxygen and moisture in flexible packaging is nowadays from metallised film layer or a Polyvinylidene chloride PVDC coating added in a multi-layer film.

Both of these solutions do not allow the packaging film to be recycled, so to reuse natural resources.

Our solution is to use our barrier additives in a mono-material film which allows to prevent food spoilage in maximising food shelf life and recover plastic waste to generate new products.

According to CEFLEX's Guidelines, our concept of having a barrier additive in a Polypropylene (PP) or Polyethylene (PE) mono-material packaging film would be categorised as mechanically recyclable as it allows:

- to have greater than 90% of the structure in PE or PP

- to keep film color "clear, natural or pale "

- to maintain density < 1 g/cm3 to sort PE or PP waste

In conclusion, CIERRA™ - BR barrier solutions help moving from a linear economy “what we take is lost” to a circular economy with the reuse of mono-material film packaging.

To understand how work CIERRA™ -BR solutions, read our blog “High Gas Barrier Coating Using Non-Toxic Nanosheet Dispersions for Flexible Food Packaging Film

References

https://www.scg.com/sustainability/circular-economy/en/

https://www.ellenmacarthurfoundation.org/circular-economy/concept

Introduction to a new 2D material: layered double hydroxid...

The interesting move of brand owners to Paper Packaging

By employing this new class of inorganic adjuvants, more e...