The automotive sector is shifting gears and moving toward a greener future.

Passenger EV sales jumped from 450,000 in 2015 to 2.1 million in 20191 and will continue growth after COVID break.2

According to a new report by Bloomberg New Energy Finance, 58% of global passenger vehicle sales in 2040 will come from electric vehicles3 driven by the

European and Chinese markets, which are expected to represent 72% of all passenger EV sales in 2030.

European and Chinese authorities push the adoption and development of electric vehicles by setting up policy support, taking the form of European vehicle CO2 regulations and China’s EV credit system, fuel economy regulations, and city policies restricting new internal combustion vehicle sales.

With this increasing demand, automakers are accelerating their EV launch plans.

Light weighting will be key in the design of these new EV cars. As well vibration resistance, distribution of the stress, safety and durability aspects of the battery will be critical. So adhesives have emerged as an ideal solution to address these issues and particularly Polyurethane adhesives when the application requires vibration inhibitions, gap variations due to thermal differences between substrates.

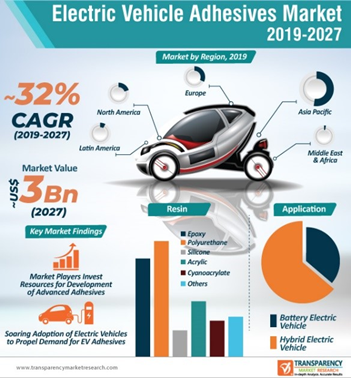

EV Adhesive Market

https://www.marketsandmarkets.com/Market-Reports/electric-vehicle-adhesive-market-194059535.html

Polyurethane (PUR) systems are really popular due to their unique combined properties such as the adhesion to almost any surface regardless its porosity, high fracture resistance, gap-filling capabilities, cost efficiency, high adhesion strength and fast curing, …

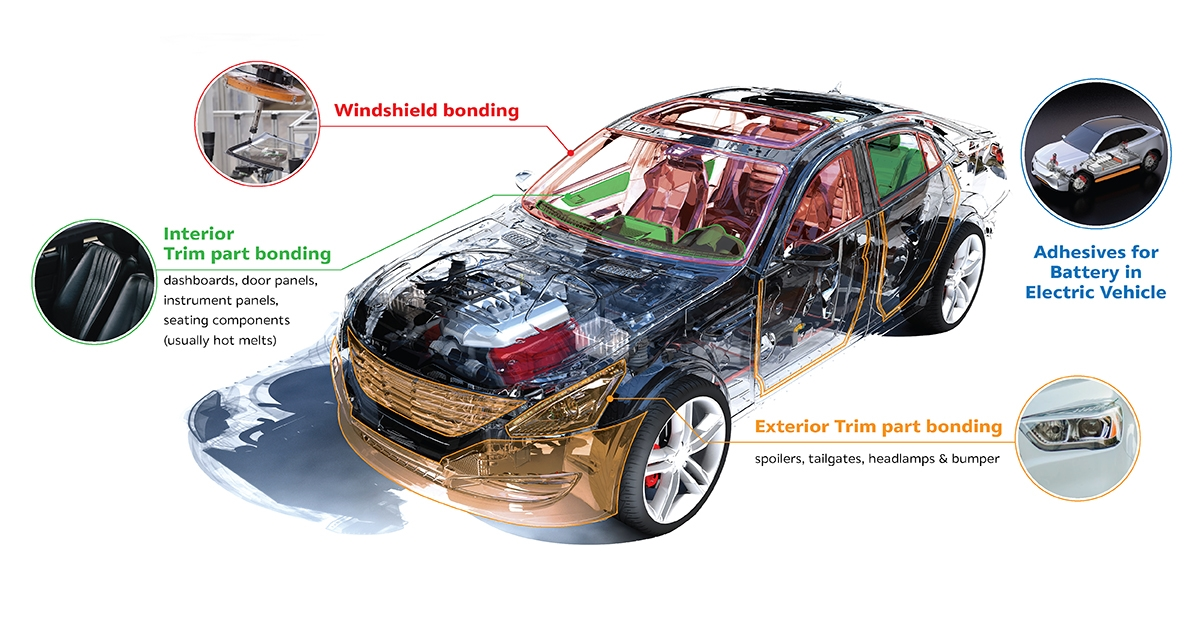

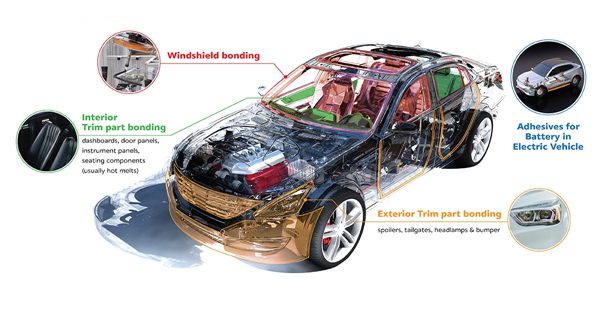

Typical applications are or will be for instance glass bonding and the assembly of Trim parts which is similar for combustion cars.

Automotive Adhesives and Sealants

Automotive Adhesives and Sealants

One additional big application will be the battery assembly, for which adhesives will have a critical role.

The adhesive will have to maintain mechanical integrity between the cells, ensure that the cells are aligned and fixtured in place while eliminating cell movement that can be caused by vibration, acceleration, and deceleration during vehicle operation.5

In conclusion, Adhesives particularly Polyurethane systems play a vital role in the advancement of vehicle electrification technology. Currently, around 15 kg of adhesives are used in a car on an average. This amount is likely to increase in the next few years.

References

- https://about.bnef.com/electric-vehicle-outlook/

- https://www.forbes.com/sites/sarwantsingh/2020/04/16/the-automotive-industry-gears-up-to-navigate-the-new-normal/#5b976e935c34

- https://pv-magazine-usa.com/2020/05/19/the-future-of-cars-is-electric-but-how-soon-is-this-future/

- https://www.marketsandmarkets.com/Market-Reports/electric-vehicle-adhesive-market-194059535.html

- https://www.adhesivesmag.com/articles/97601-electric-vehicles-and-the-growing-significance-of-adhesives-and-sealants-for-battery-assembly

Introduction to a new 2D material: layered double hydroxid...

The interesting move of brand owners to Paper Packaging

By employing this new class of inorganic adjuvants, more e...